Velocys’ Altalto

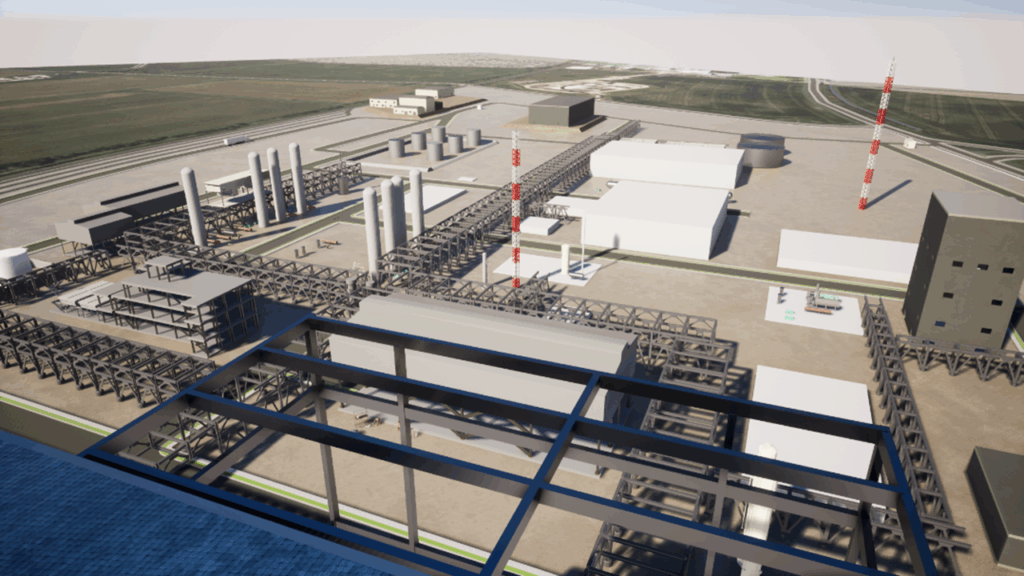

From First-of-a-Kind to future-proof, Velocys’ Altalto is converting municipal waste into 23 ktpa of SAF in the UK, using a modular design for global growth.

Velocys’ Altalto Immingham project aims to be one of the UK’s first commercial-scale sustainable aviation fuel (SAF) plants. Drawing on lessons learned from an earlier basis of design, the company has reshaped the process layout to include new gasification technology and a more modular design to promote greater plant integration and robust partnerships. By converting municipal waste into low-emissions jet fuel, the Altalto project illustrates how experience and persistence can turn early setbacks into a platform for global SAF growth.

| KEY FACTS | |

|---|---|

| Official project name | Altalto Immingham Ltd |

| Parent company | Velocys, owned by a consortium of impact investors with a climate focus. Members include Carbon Direct Capital, Lightrock, GenZero, and Kibo Investments |

| Location | Immingham, Humber region, United Kingdom |

| Project stage | Pre-FEED; FEED expected Q1 2026; operations by 2030 |

| Sector | Sustainable Aviation Fuel |

| Capacity | 23 ktpa SAF annually |

| Feedstock | Municipal solid waste (MSW), commercial & industrial waste |

| Carbon benefit | 100,000 tonnes CO₂e savings annually, >70% lifecycle reduction vs. fossil jet fuel |

| Key milestones | • Technology reconfiguration and scale-down strategy Q1 2026 • Market reach and investment bridging 2025 • Planning consent for site development secured 2025 • Received an Advanced Fuels Fund (AFF) round three grant from UK Department for Transport (DfT) in 2025 |

Company vision and motivation

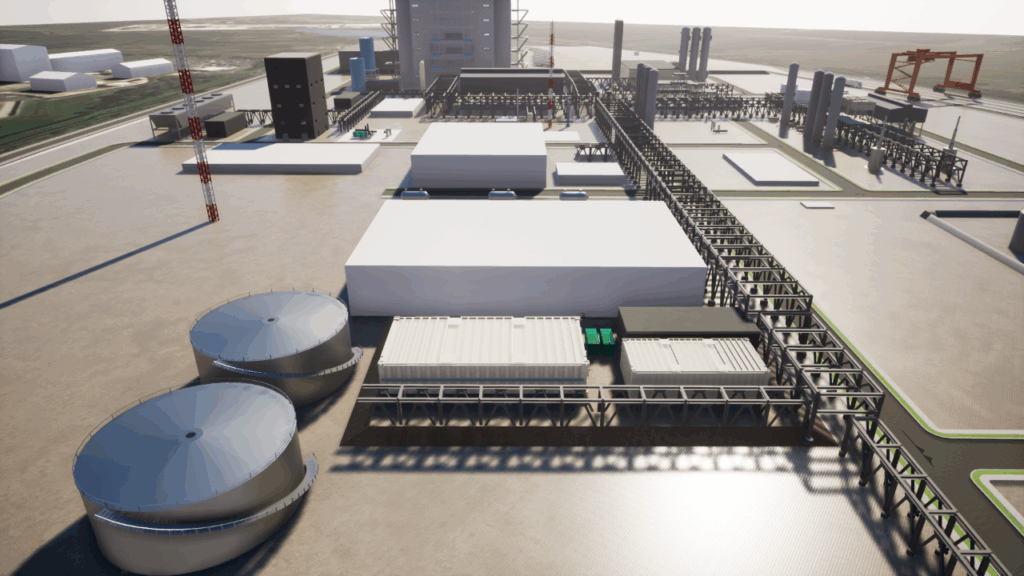

Velocys has been at the forefront of Sustainable Aviation Fuel (SAF) development for over two decades. Its UK based Altalto project is designed to deliver second-generation SAF, which is projected to dominate supply by 2050. With regulations and decarbonisation strategies driving strong market growth, first-generation SAF cannot meet demand alone due to finite feedstock supply. First-generation SAF is produced via a Hydroprocessed Esters and Fatty Acids (HEFA) process, which refines oils and fats from sources such as used cooking oil or animal fats. One way to produce second-generation SAF is through the Fischer-Tropsch (FT) process, which can utilise a much broader range of non-food feedstock waste materials, including municipal waste and agricultural residues. Using this feedstock has a dual benefit: it is directed to a higher-value application and is diverted from being burnt for energy generation, bringing greater long-term economic and climate benefits. In this FT process, waste is first converted into a gas, which is then transformed into liquid fuels that are upgraded for use in aviation.

To decarbonise aviation we need a variety of technologies, including second-generation biofuels and e-fuels.

— Andy Bensley

Chief Operating Officer, Velocys

With aviation under pressure to decarbonise, and the industry’s thin margins, the company aims to deliver technically viable, commercially investable and scalable solutions.

From FOAK to Future-Proof

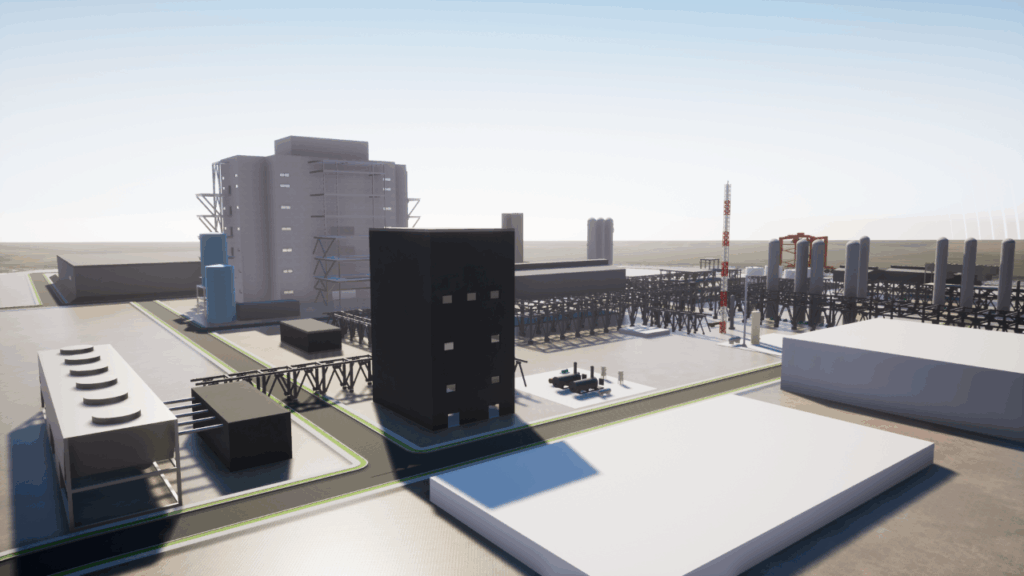

Velocys’ Altalto project represents a strategic pivot in the race to develop commercial-scale clean aviation fuel. Drawing on lessons from its initial basis of design, the company has shifted to a modular approach that reduces costs, minimises integration risks and strengthens the business case.

Despite gasification having a high ‘technology readiness level’ scoring and the project being at the FEED stage, there was a perception of risk around the size of the original units and the associated capital outlay. This led to a change in technology, focusing on process efficiency and optimisation to bring costs down. By comparison, using this approach has resulted in a significant reduction in capex costs at a small-scale demo project where Velocys is piloting electrified biogas to SAF in Uruguay. The company believes its FT technology reduces the cost of producing sustainable fuels, positioning it as a critical part of solutions capable of making second-generation SAF affordable.

We had to divert from our original route. We couldn’t achieve the funding requirements to continue because of the capital lift and perceived technology risk. So we fixed that.

— Andy Bensley

Chief Operating Officer, Velocys

As one of the few Fischer-Tropsch (FT) technology providers with commercial experience, Velocys is positioning Altalto as a replicable model for waste-to-SAF and aims to capture share in the emerging SAF market.

Finding the correct production scale is crucial, as the limited supply of feedstock and the scale of conventional chemical production impose constraints on both sides. Transporting waste over long distances is unfeasible due to cost and carbon intensity. It is also challenging to scale down conventional technologies because economies of scale make the capital intensity of small production facilities infeasible. The company addresses this challenge by offering a modular yet scalable technical solution. The Altalto project is linking proven FT technology to abundant waste feedstocks and reducing risk to demonstrate that SAF can be both bankable and socially beneficial.

Challenges

The path to this point has been anything but straightforward. Velocys had to adapt its design and financing in response to a changing market environment.

- Perceived technology risk and high manufacturing costs led to a switch in gasification licensor technology and a shift to a new production strategy with a strategic partnership with Morimatsu for manufacturing

- Policy and market uncertainty: Perceptions of a SAF mandate change and Contracts for Difference (CFD) have made it harder to secure investor confidence

- Feedstock logistics: Securing high volume and reliable supply chains for municipal waste for second-generation SAF projects is complex and costly

Benefits of being a first mover

Despite setbacks, Velocys’ early entry into the SAF market has provided strategic advantages:

- Credibility with investors and regulators as one of the few FT technology providers with commercial operating experience. Velocys and Altalto are lowering investor concerns about FOAK status.

- Integration expertise refined from its initial basis of design reduces risks for Altalto Immingham and future plants.

- Market influence allowed Velocys to shape offtake agreements and secure partial UK government Advanced Fuels Funding. It is passing learnings onto the burgeoning UK SAF industry and has the potential to influence future government policy.

- Partnerships with EPC contractors, technology providers and international partners are enabling cost reductions by up to half for smaller plants.

Perpetual support of R&D efforts, pilot and demonstration projects is key. Even small-scale demos deliver large-impact learning in operations. Within a very short period of time, we’ve achieved process optimisation, new supply chains and engineering expertise that has trimmed project capital costs by almost half.

— Andy Bensley

Chief Operating Officer, Velocys

Lessons learnt

The journey has highlighted several critical lessons for the broader SAF sector:

- Start small and scale carefully: modular design reduces risk and improves investability

- Integration is key: Owning the integration of the front-end avoids costly commissioning errors

- Policy certainty drives investment: Clear, stable regulation and mechanisms like Contracts for Difference are vital for securing financing

- Partnerships matter: Successful projects require strong collaboration across developers, EPC contractors, and technology providers

- Continuous adaptation: Flexibility in technology, geography and financing provides a foundation for long-term resilience

The size of the project is not by accident. It is based on where investor appetite is right now. That is a direct learning from the previous raise and project activities. It falls within a bandwidth where we think that there is sufficient appetite across equity and debt.

— Andy Bensley

Chief Operating Officer, Velocys

Looking ahead

Today, Velocys is better positioned than ever. With a modular approach, first-hand expertise and strategic partnerships, the company is ready to deliver projects that meet both environmental and commercial imperatives. The project expects to be FEED-ready in early 2026, at FID by 2027 and operational by 2030.