Ecocem

Ecocem is pioneering the industrial-scale rollout of ACT, a breakthrough low-carbon cement technology that can cut CO₂ emissions by up to 70% at its Dunkirk facility in France.

Ecocem is pioneering the industrial-scale deployment of low-carbon cement in Europe. Its Dunkirk facility in Northern France is set to become the first commercial production site for ACT (Advanced Cement Technology), a breakthrough innovation that can cut CO₂ emissions from cement manufacturing by up to 70% with no significant cost increase. Backed by strong partnerships, public support and a compelling business case, Ecocem is on track to deliver ACT to market by 2026.

| KEY FACTS | |

|---|---|

| Official project name | Ecocem ACT Dunkirk |

| Location | Dunkirk, France |

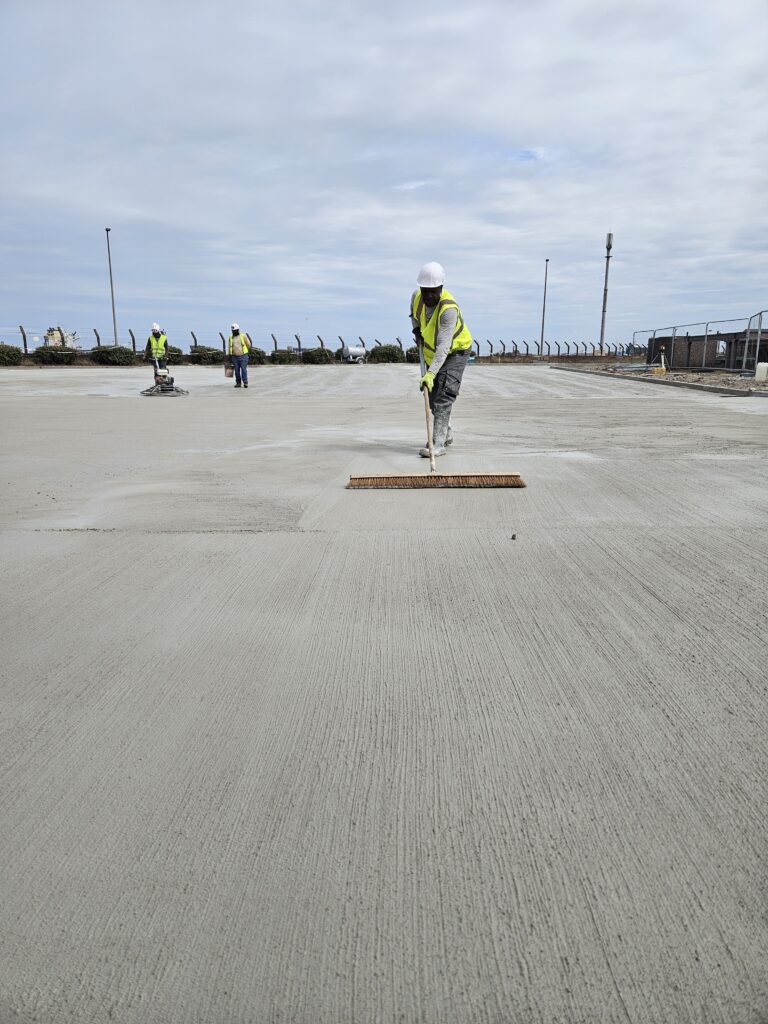

| Project stage | Under construction |

| Sector | Cement and Concrete Technology |

| Customers | Ready mix concrete manufacturers, precast manufacturers, general contractors |

| Jobs/ employees | 15 new jobs + approximately 75 indirect jobs |

| Total project investment | €50 million including €4 million public grant |

| Capacity | 300,000 tonnes/year of ACT cement (initial), expanding to over 1 million tonnes/year |

| Key facts | • Over the past decade, Ecocem has built one of the most advanced R&D and Innovation programmes for the decarbonisation of the cement industry. Ecocem is recognized globally for its leadership on low carbon cements and technologies for concretes and mortars, with 24 patents and 25 peer-reviewed publications since 2014. • In France, we have an in-house team of 30 highly qualified engineers and technicians with multidisciplinary backgrounds and of more than 10 nationalities. We operate across three Labs – Ecocem Research & Innovation Centre, Chilly Mazarin, and labs in University of Paris-Saclay and University of Toulouse with access to the most advanced scientific research facilities. • Internationally, we collaborate with universities funding 17 high-level researchers and have a Science Advisory Network with 14 established experts in low carbon cement and concrete. |

| Key milestones | • ACT technology announced in 2022 • European Technical Assessment (ETA) obtained 2023 • ACT to be included in the EU cement norm from 2026 •ACT supplied to 30 demonstration projects in Western Europe commencing mid-2024 • Demonstrator project for ACT Technology funded by Innovate UK, the first structure of its kind, 2024 • Technical Readiness Level (TRL) 7 • Dunkirk ACT plant construction started early 2025 • ACT delivery to market expected for second half of 2026 • Achieved ASTM C1157 certification in North America second half of 2025 |

Founding Vision

Cement accounts for nearly 8% of global CO₂ emissions. Ecocem has spent more than a decade developing ACT (Advanced Cement Technology) that cuts emissions by replacing most of the clinker – the most carbon-intensive ingredient in cement – with alternative materials.

The low-clinker formula delivers up to 70% lower emissions compared to conventional cement, without compromising performance or cost. This is crucial in a market where the most widely advocated solutions for low or zero-carbon cement can increase costs to the end customer by up to two or three times. Importantly, Ecocem ACT can be used within existing construction practices, with high performance levels and as a ‘drop-in’ solution, making rapid adoption feasible. During the development stage over 30 demonstration projects were completed covering the most common applications such as building foundations, columns, and slabs.

The Dunkirk plant will be the first to host a full-scale ACT production line, serving Northern France, the Paris region, and export markets. ACT uses locally available blast furnace slag and mineral additions with the site being strategically located in a Regional Aid Zone and benefiting from robust port infrastructure and proximity to major construction markets.

For general purpose cement use, there’s no reason why ACT shouldn’t be able to supply over 90% of the market.

— Donal O’Riain

Founder and Group Managing Director, Ecocem

Charting a way to the market

Traditional cement manufacturing has remained largely unchanged for 200 years, with the traditional regulatory environment creating a barrier for innovative projects like ACT. Recognising this, Ecocem worked early to ensure regulatory access. The technology has already obtained a European Technical Assessment (ETA) and is undergoing certification by France’s Centre Scientifique et Technique du Bâtiment (CSTB), while the European cement norm (EN 197) will be revised by the end of 2026 to include ACT. Concrete standards are also being updated in France, Belgium, and the Netherlands.

Once we are recognised by the norms, selling the material is not a major problem because ACT is price competitive and there is genuine interest in low-carbon solutions across the construction market now.

— Donal O’Riain

Founder and Group Managing Director, Ecocem

Financing and Partnerships

The €50 million project is financed entirely with debt, supported by a €4 million public grant. Ecocem’s strong balance sheet and 22 years of profitable trading enabled this rare financing structure.

The supply chain is secured through long-term partnerships: blast furnace slag from ArcelorMittal, ground clinker from established producers and minerals via a joint venture with CB Green (part of Group CB), in Northern France. The joint venture partner will hold a 30% stake in the limestone grinding unit, with Ecocem taking the remaining 70%. These partnerships guarantee the raw materials needed to deliver ACT at scale.

The banks were only concerned about one thing: will you be able to sell this product in the marketplace? We had to convince them that the work we are doing with the norms would be ready in time to for us to access the market.

— Donal O’Riain

Founder and Group Managing Director, Ecocem

Scaling the technology for global impact

The Dunkirk facility is just the start of a wider roll-out. With construction underway, Ecocem plans to expand ACT capacity in France to 1.9 million tonnes/year by 2030, reducing CO₂ emissions by 800,000 tonnes annually. Future plants will be located in Dunkirk and Fos-sur-Mer, with the Dunkirk plant configuration designed to allow it to expand in the longer term. The company is planning to take an investment decision on the expansion project in the course of 2026. Increased capacity should be operational before the end of the decade.

Between planning, permitting and construction, it’s about a three-year cycle from a decision to increase capacity to actually having additional capacity available.

— Donal O’Riain

Founder and Group Managing Director, Ecocem

Ecocem has also commenced licensing of its ACT technology to external cement partners. In November 2024, a partnership was signed with Titan Group, active in Greece, Central Europe and North America to develop ACT formulations using natural pozzolanic materials. The partnership includes efforts to revise Greek concrete norms to allow innovations in low-carbon cement.

Beyond Europe, Ecocem is exploring ACT applications in India and Africa, where the technology offers a compelling value proposition: tripling cement output per kiln with minimal investment. This is especially attractive in high-growth markets with limited capital.

In India, the major challenge to the cement industry is not reducing CO2 emissions like in Europe. Their first priority is increasing cement capacity without having to invest too heavily.

— Donal O’Riain

Founder and Group Managing Director, Ecocem

Lessons Learned and Scalable Strategies

Ecocem’s journey shows that long-term commitment to R&D can yield transformative results. Partnerships are key to accelerating adoption. Ecocem is also working with major contractors such as Bouygues Construction, Vinci Construction and Eiffage, who they have found to be more open to innovation than traditional cement producers.

Our main criteria for working with a partner is how fast they can move. If you’re ready to move fast and ambitiously, then we’ll work with you.

— Donal O’Riain

Founder and Group Managing Director, Ecocem

The model is well-suited for Europe, where carbon pricing and regulation create a favourable environment. But Ecocem is open to expansion in multiple guises and would consider licensing to those who want to move fast.

We want to license this technology globally. The real challenge is decarbonising cement worldwide, not just in Europe.

— Donal O’Riain

Founder and Group Managing Director, Ecocem

Ultimately, Ecocem’s experience in Dunkirk shows that with innovation, the right partnerships and supportive policies, clean technologies can move rapidly from laboratory to market and can globally allow one of the world’s most carbon-intensive industries to decarbonise on a trajectory compliant with 1.5°C of global warming.