Envision

Green hydrogen and ammonia are essential for the transformation to clean industry and the Chifeng Green Hydrogen Net Zero Industrial Park is leading the way.

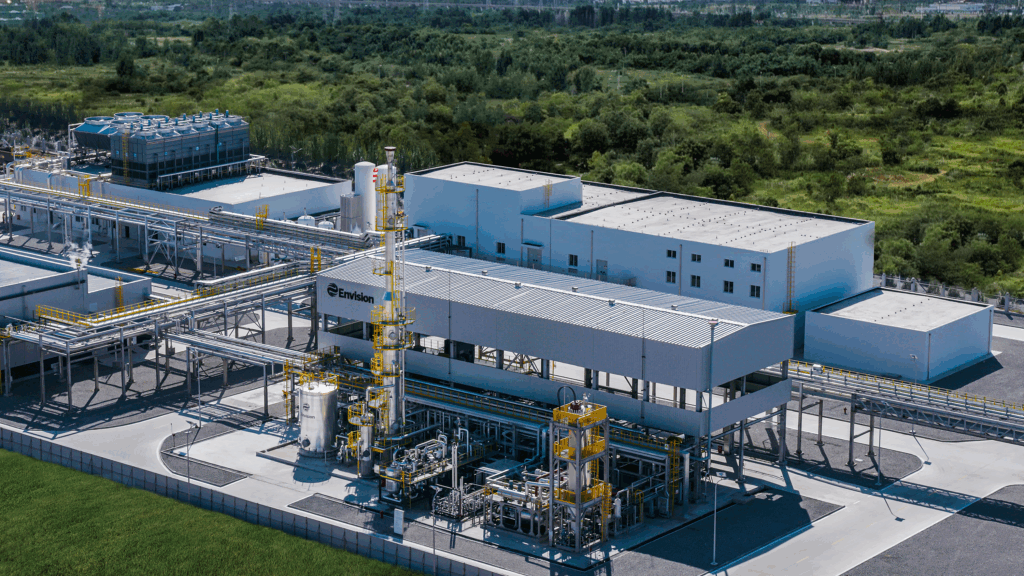

Green hydrogen and ammonia are essential for the transformation to clean industry, but are still viewed as premium products with high prices. The Envision Chifeng Green Hydrogen Net Zero Industrial Park in China is challenging this idea. As the world’s largest green ammonia plant, it is determined to make the green hydrogen economically competitive with fossil fuels without relying on subsidies or regulations.

| KEY FACTS | |

|---|---|

| Official project name | Chifeng Green Hydrogen Net Zero Industrial Park |

| Location | Chifeng, China |

| Project stage | Operational |

| Sector | Chemicals, ammonia |

| Customer | Offtake agreements signed |

| Total project investment | €1.5 billion |

| Capacity | 320,000 tonnes of ammonia per year |

| Key milestones | • Initiated the idea in Jan, 2022 • Acquired land by Q3 of 2022 • Construction of pilot phase was kicked off in Apr, 2023 and COD of pilot phase was in Mar, 2024 • The construction of phase 1(300K tonnes per year) was kicked off on Apr, 2024 with COD on 8th July, 2025 |

A founding philosophy of self-belief and determination

As a global leader in full-stack green hydrogen technology, the international cleantech leader Envision Energy is driven by the goal of making green hydrogen and green ammonia economically competitive with conventional fuels, without relying on subsidies or regulations.

The company’s philosophy emphasises that green hydrogen should not be an expensive commodity accessible only to a select few at a premium price. Instead, it should become a mainstream solution adopted as widely as oil, gas or electricity.

The first key step to its goal is to build Chifeng Hydrogen Net Zero Industrial Park in Inner Mongolia, China by Envision’s integrated solution from wind to ammonia. This 100% off-grid facility is powered by renewable energy, wind and solar, and capable of producing 320,000 tonnes of green ammonia annually.

It became fully operational in July 2025 thanks to a combination of this bold vision with a continuous improvement mindset: a commitment to relentlessly reducing costs across all project parts, including renewable energy generators, electrolysers and ammonia reactors.

Green ammonia has a high potential to be the game-changing green molecule to be widely adopted in the market, for example, in bunkering and power generation to replace conventional fuels like coal or oil. Through this drive, the green hydrogen costs will be reduced and can then be used for other industries like metal.

— Frank Yu

Senior Vice President, Envision Energy

Building credibility

Envision took a deliberate approach to the park’s creation, beginning by conducting extensive feasibility studies and creating system models to test the effective integration of wind, solar, electrolysis and ammonia production. Streamlining integration was a key priority.

Once modelling confirmed the project’s technical and economic viability, the company moved into a pilot phase, to validate the technology under real-world conditions, refine processes and test the end product.

The pilot stage investment gave us time to test technology, execution and market engagement. After proving capability, we committed to full project construction, even before offtake agreements were signed.

— Frank Yu

Senior Vice President, Envision Energy

This led to the first commercial level phase and a further $1 billion investment to prove the systems could deliver at scale.

Projects of this scale will need be taken on by well-capitalized firms with the right talent and risk appetite – they need to invest early and execute large-scaled projects in a disciplined manner.

— Frank Yu

Senior Vice President, Envision Energy

In May 2025, the project’s technical foundations were verified by the Bureau Veritas certification, confirming the use of Envision’s own electrolyser technology, which is powered entirely by wind and solar energy. A milestone achievement signalling the credibility of Envision’s technological choices and integration strategy.

The facility was commissioned in July, with the first 320,000-tonne volume of green ammonia set for export and delivery in the fourth quarter of 2025. It will be the world’s first ISCC PLUS certificated green ammonia. This certification confirms that the project meets rigorous international sustainability criteria, validating its design and implementation, another breakthrough for the Chifeng Industrial Park.

Overcoming the challenge of securing customers

From the outset, the project faced the classic ‘chicken and egg’ problem: customers wanted proof of ability to deliver the product before signing offtake contracts, while financiers demanded signed agreements before investing.

Rather than waiting for either, Envision took a bold step by investing its own capital early, backing its belief in the concept and trust that it would be able to deliver. The company believed that through its extensive modelling, pilots and commitment along with its established leadership in the energy landscape it would show its credibility and bring clients to the table.

The team placed their faith in the potential of green hydrogen and in Envision’s ability to effectively integrate technologies and processes.

The process of securing customers took some time but once construction of the first phase began, going to the market and starting conversations became easier. Transparency and regular engagement was key to securing contracts. Potential customers were invited to visit the site on multiple occasions to see the work with their own eyes and the Envision team worked hard to foster partnerships.

We need to build long-term partnerships, we cannot expect to finish the deal in one phase, it’s impossible, partnerships are built up steadily, step by step as it is crucial for customers to believe in it.

— Frank Yu

Senior Vice President, Envision Energy

Envision has secured customers from Japan, Singapore, South Korea and Europe where there is solid demand. It is expecting a boost in demand resulting from the IMO’s mid-term measures session in Autumn 2025 specifically for green fuels and bunkering.

First mover advantage in a growth market

The Envision experience confirms being a first mover pays off, but it demands courage. By acting early, Envision gained credibility and won the trust of customers where others hesitated.

The company also aims to extend and replicate its integrated green hydrogen and ammonia model far beyond their first plant in China. The company aims to find new locations for expansion close to target markets like Europe and Singapore but it is waiting for demand signals before committing to further investment.

The Envision project reinforces the idea that green ammonia is a crucial stepping stone. Its early adoption not only drives down hydrogen costs, but also creates opportunities in the steel, fuel and mobility sectors. How quickly the market will expand is still an open question.